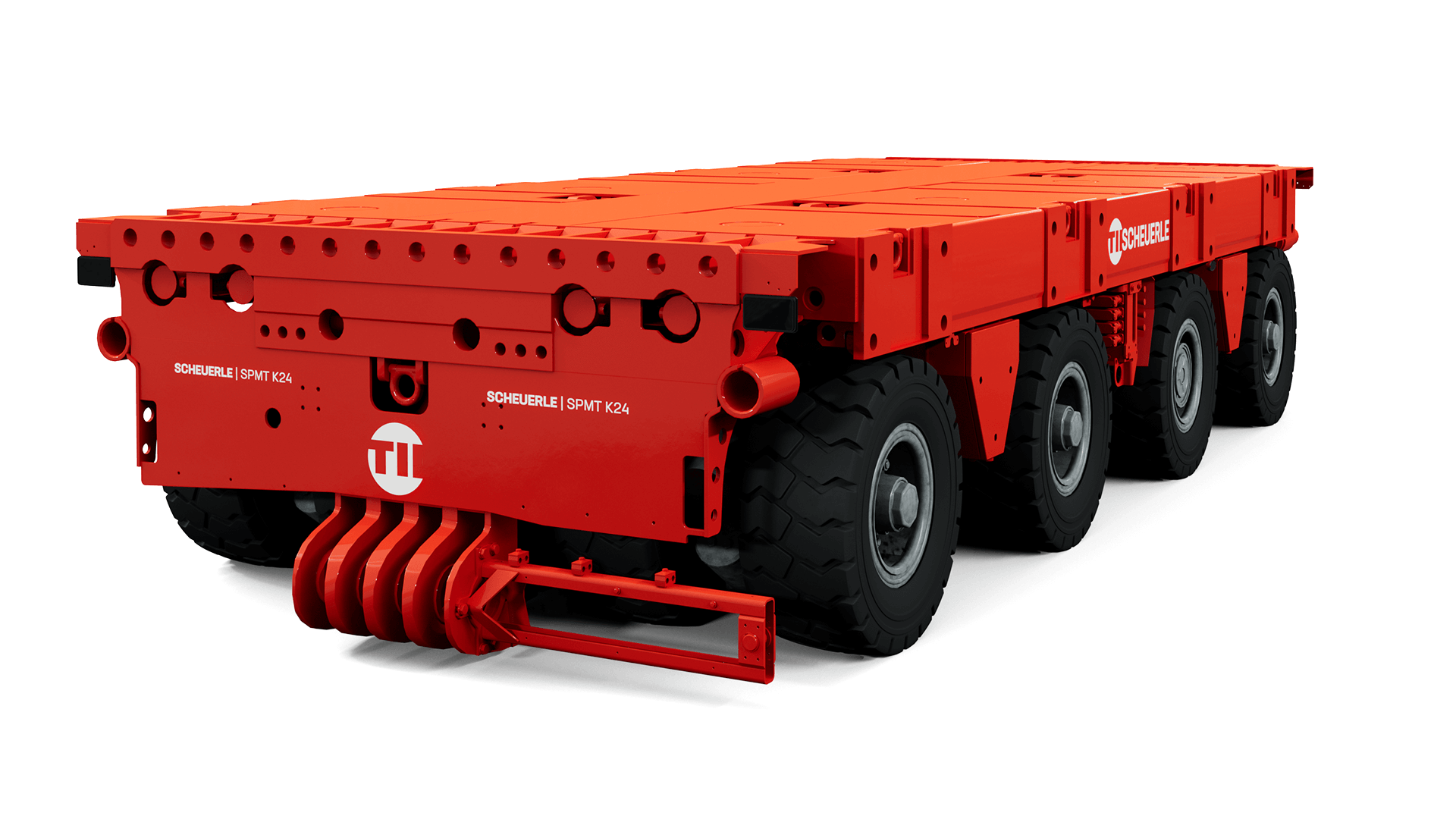

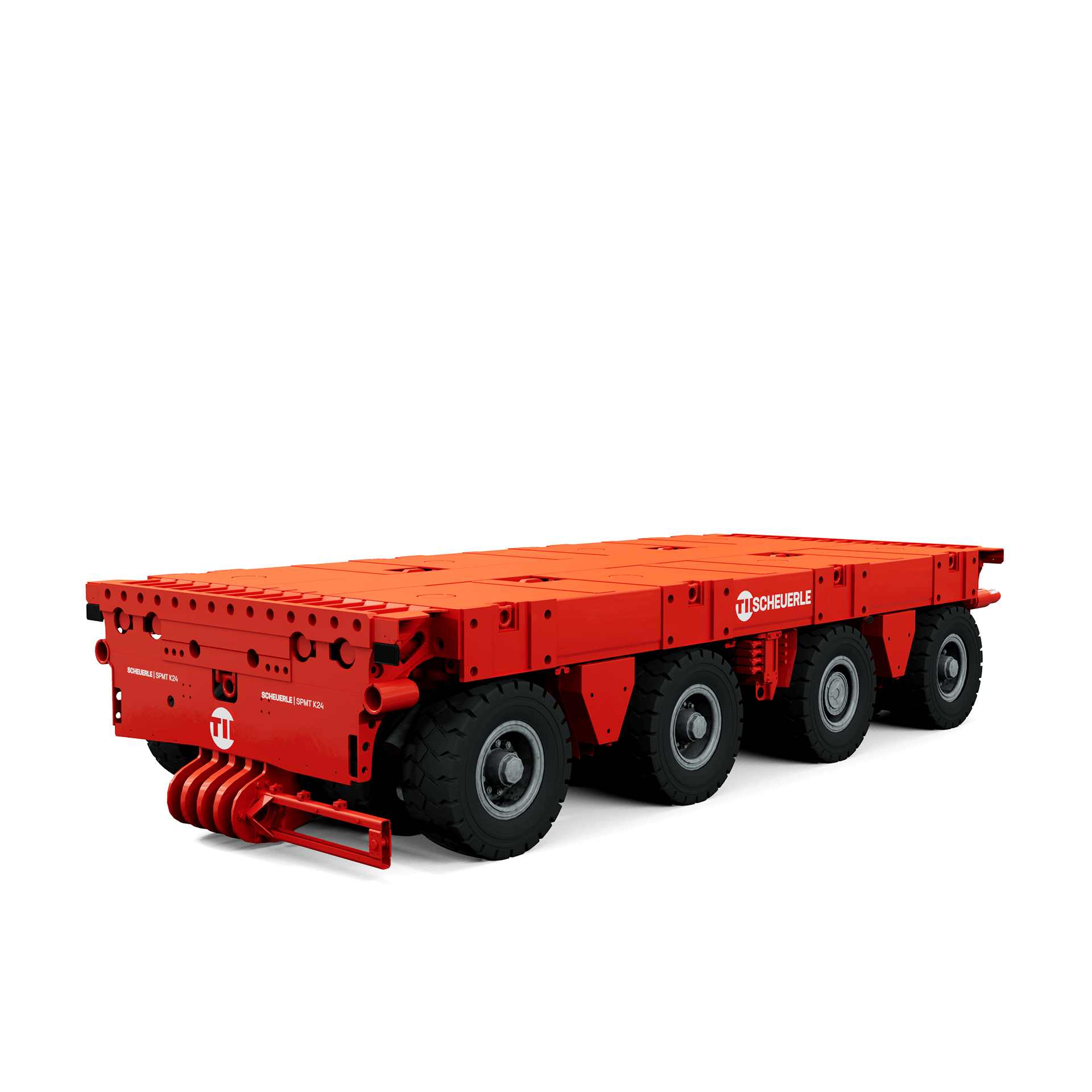

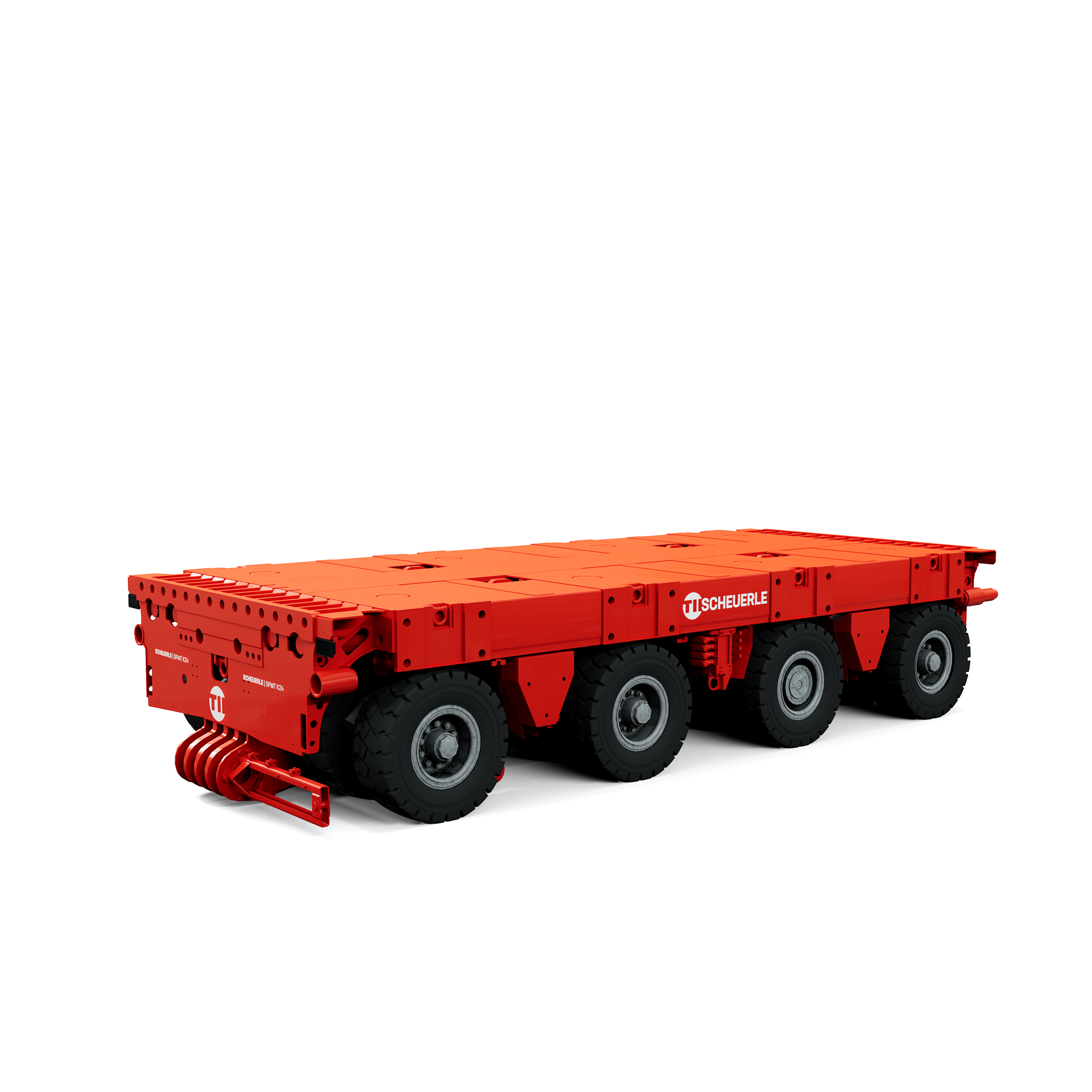

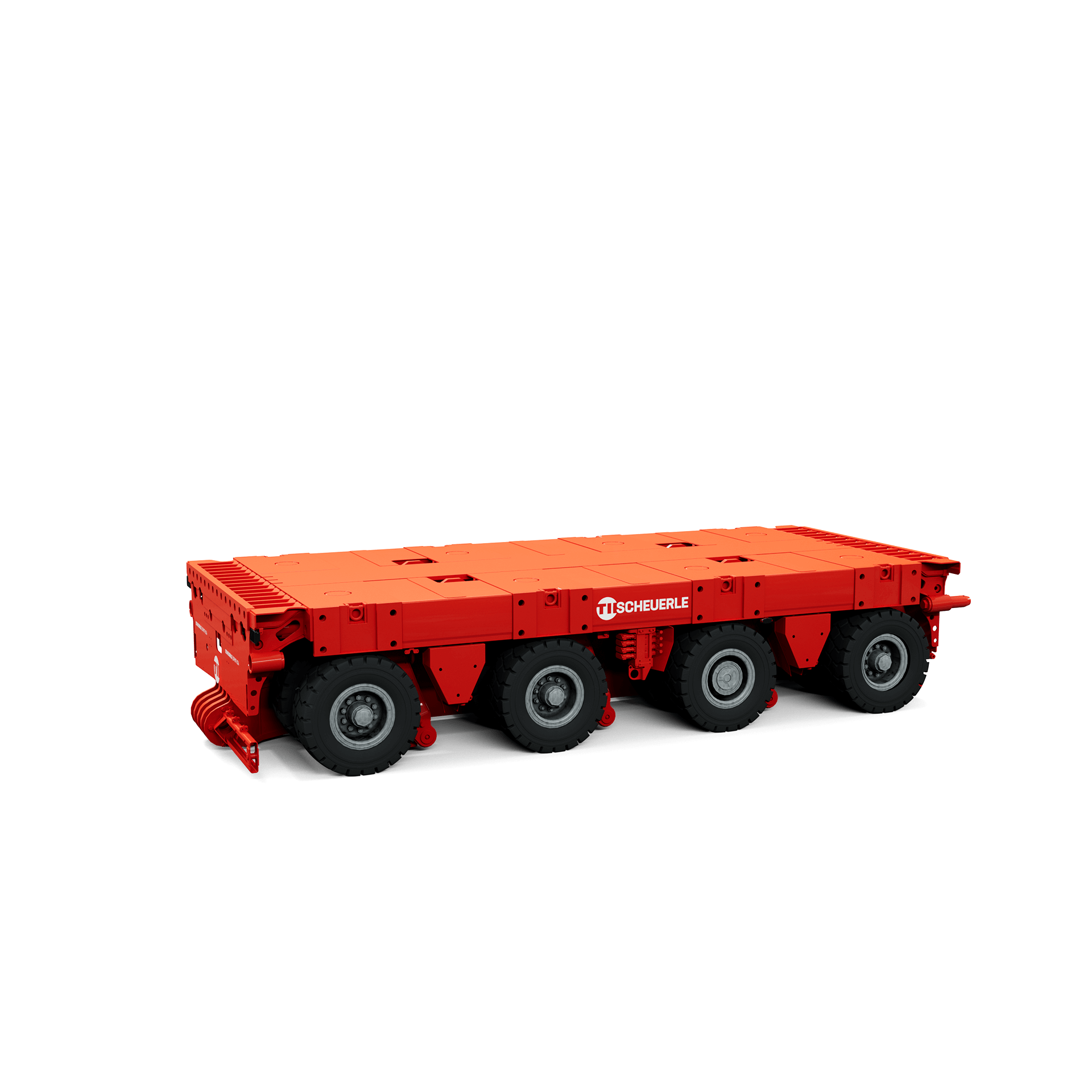

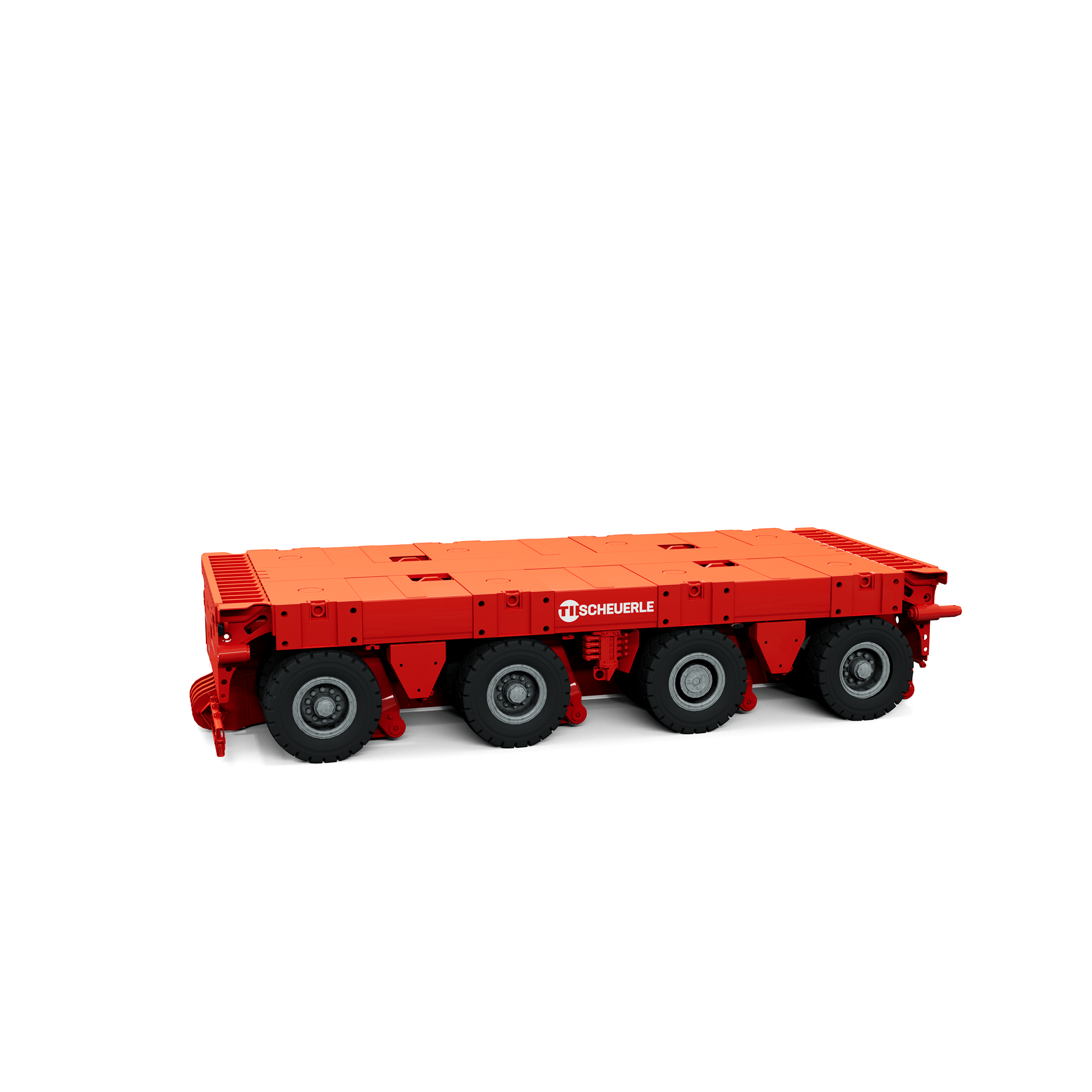

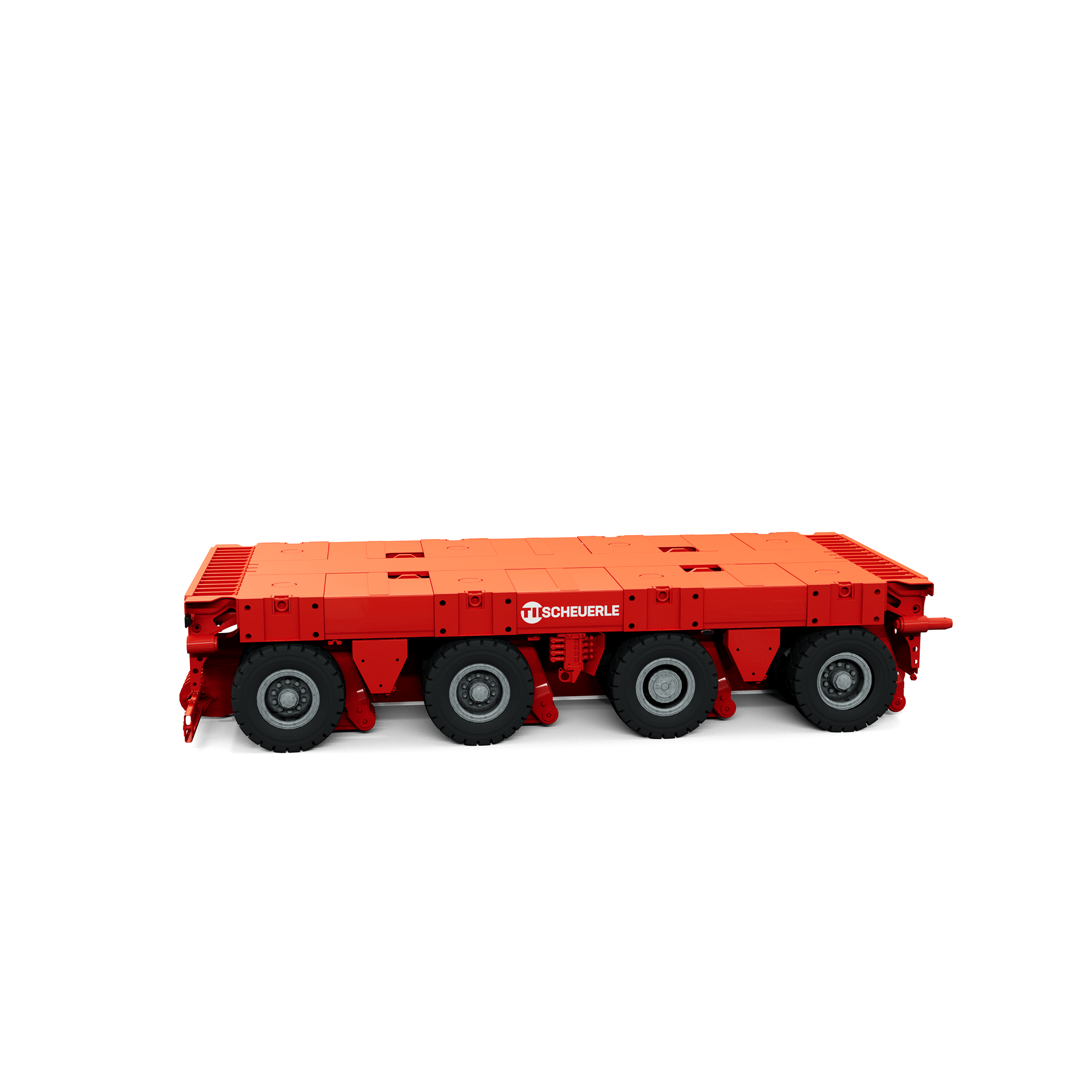

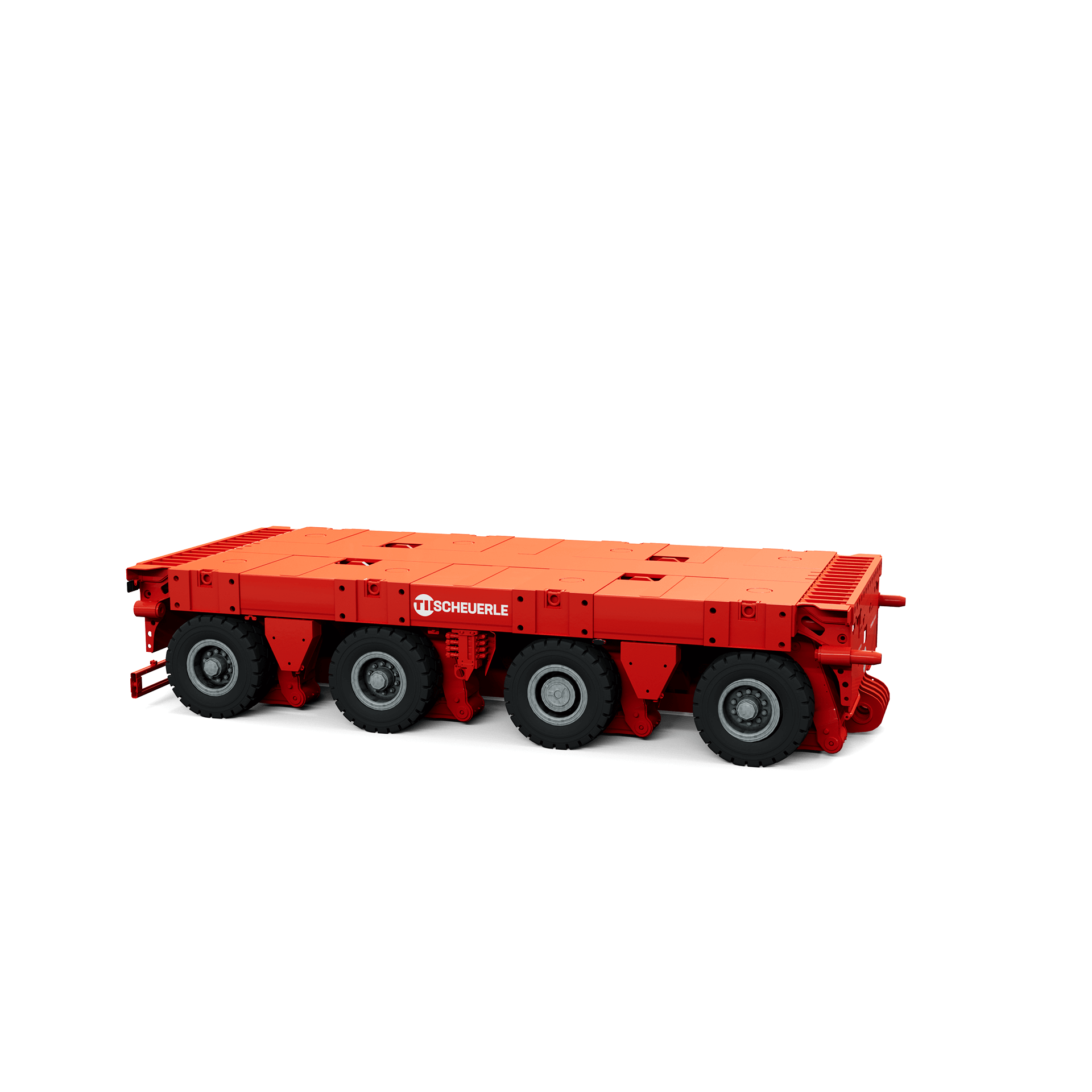

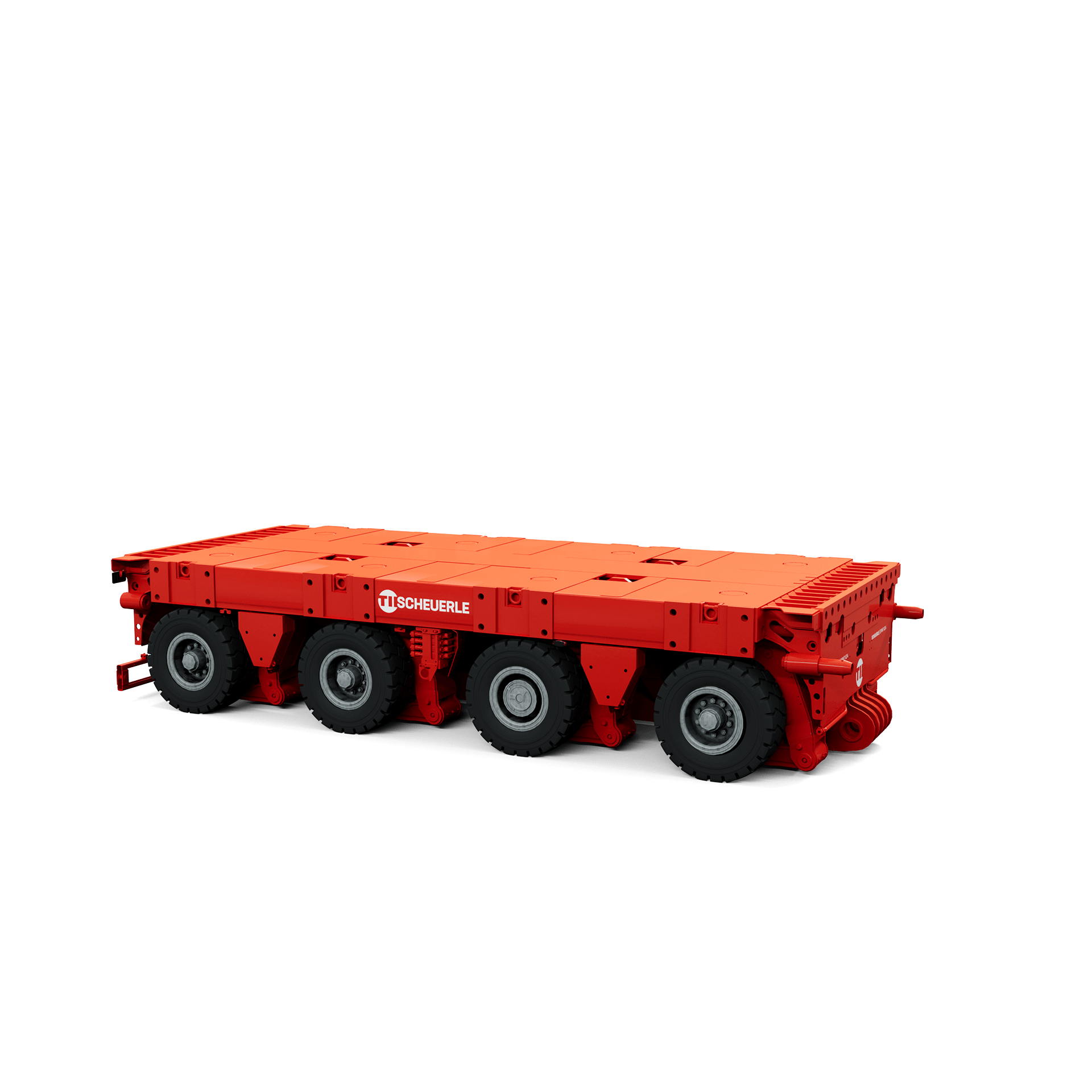

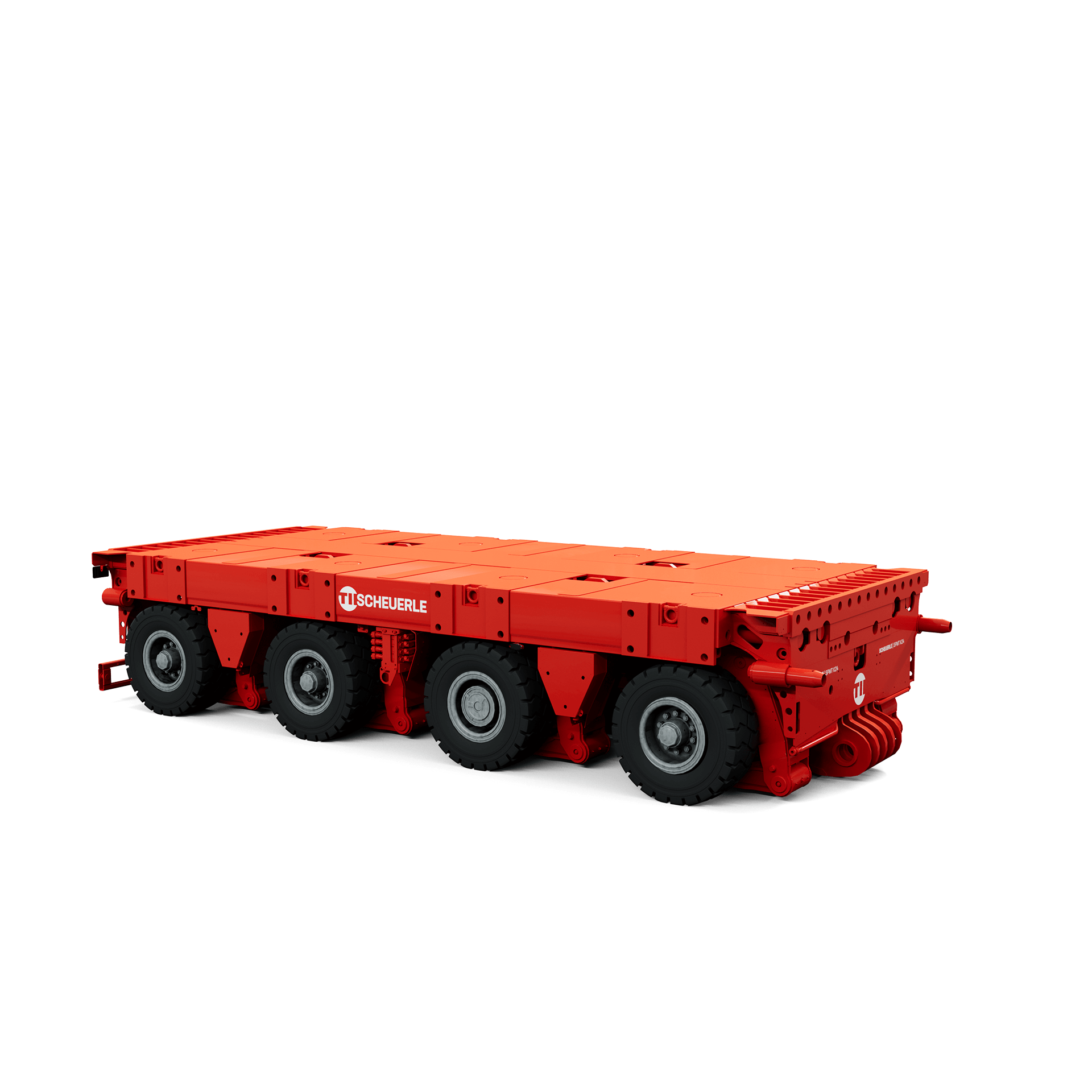

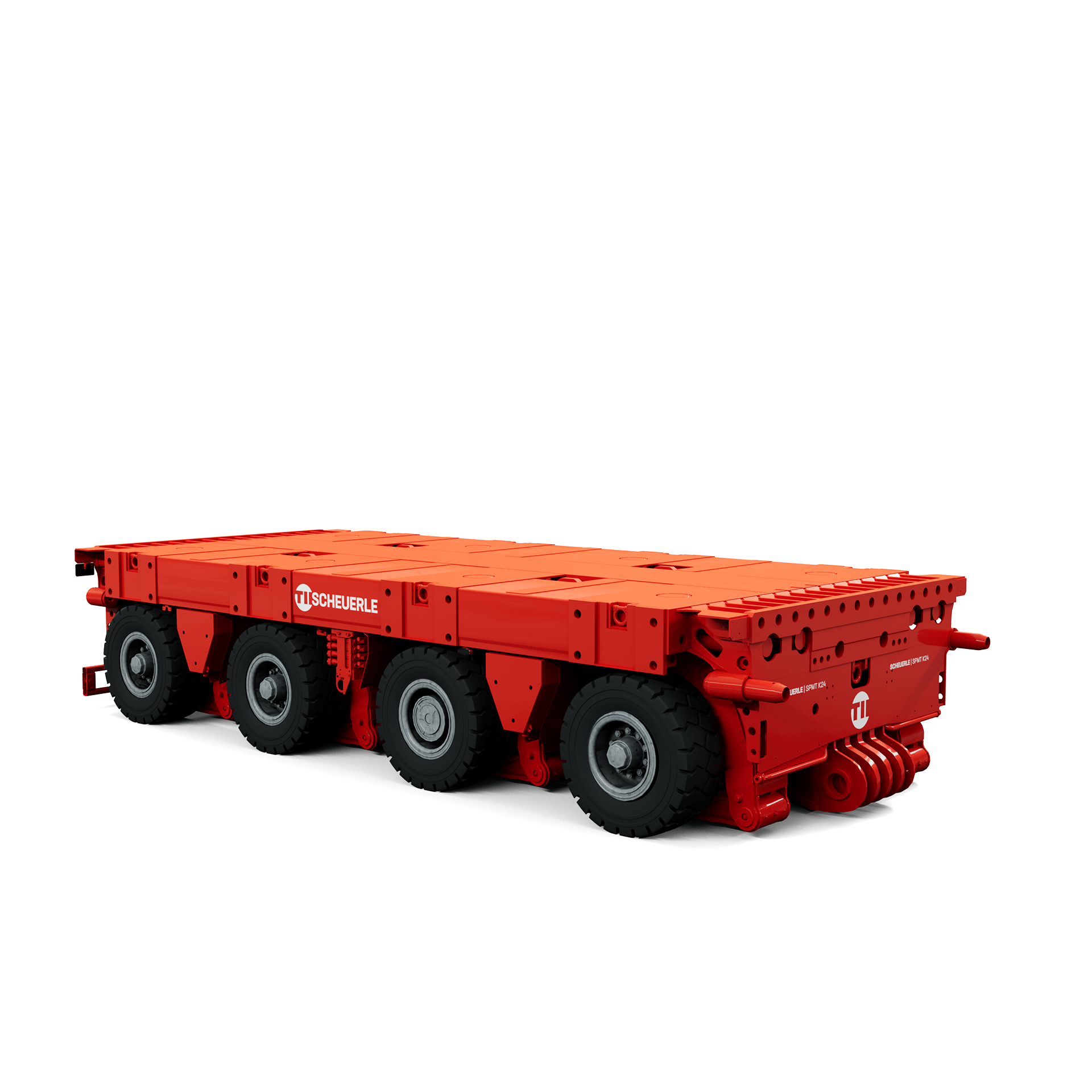

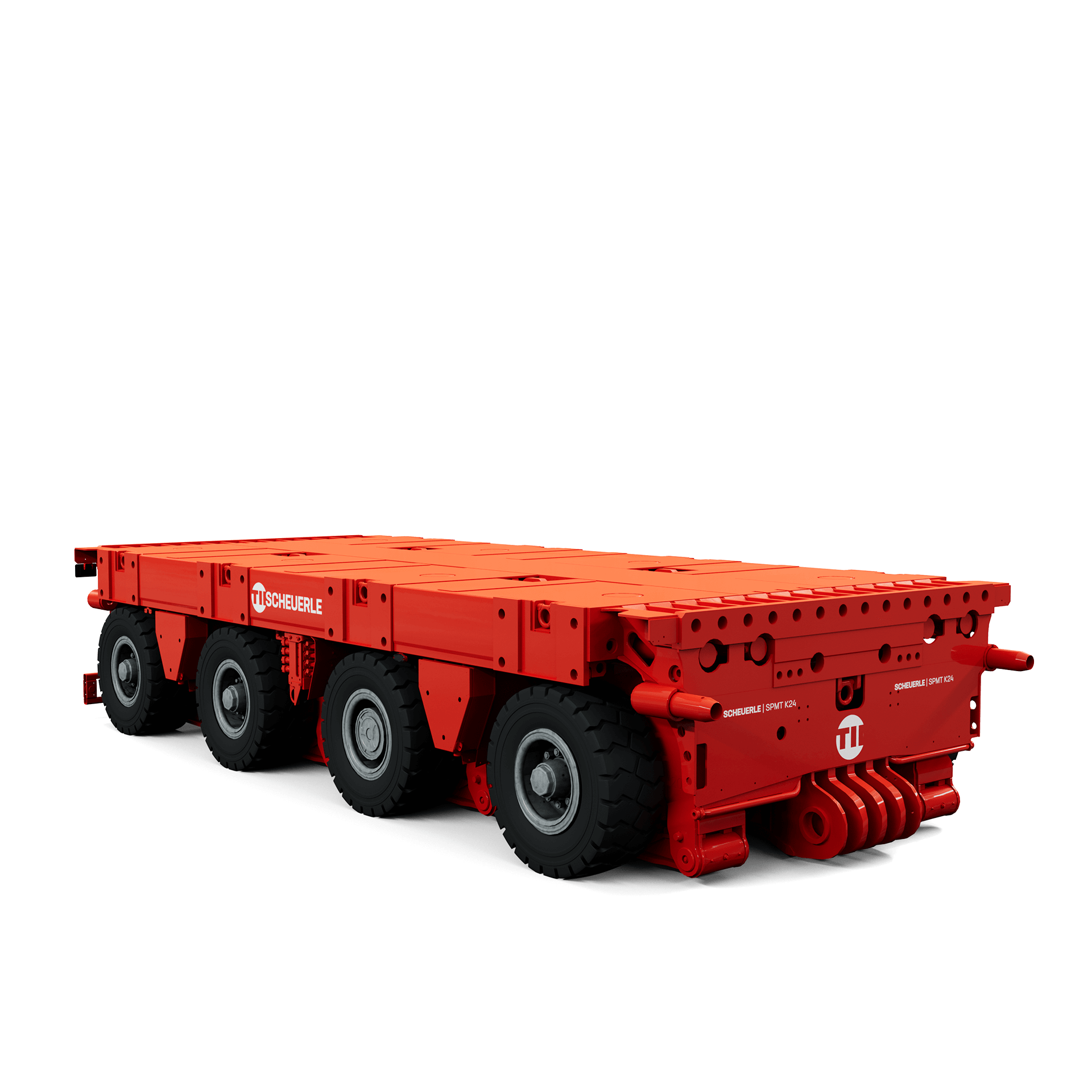

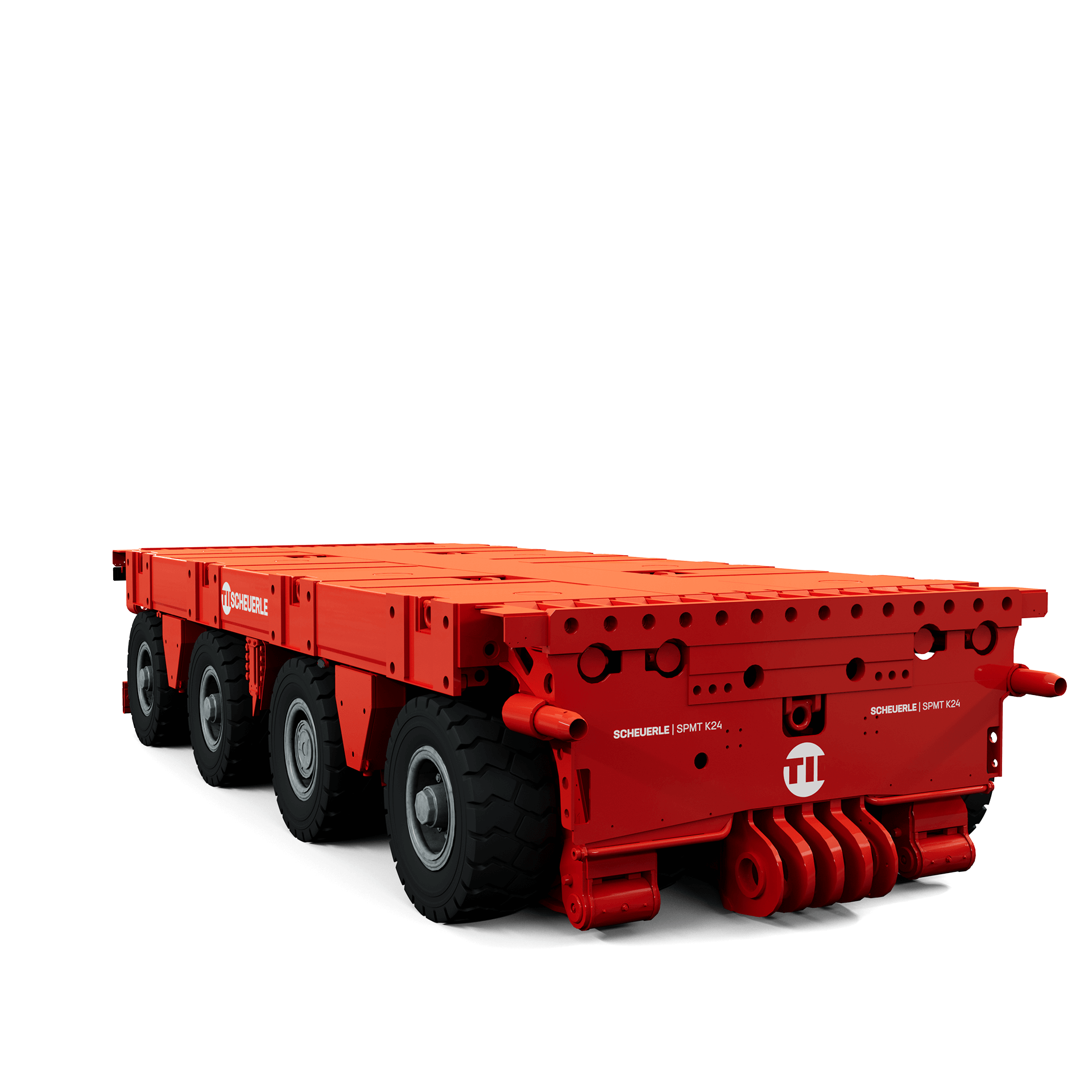

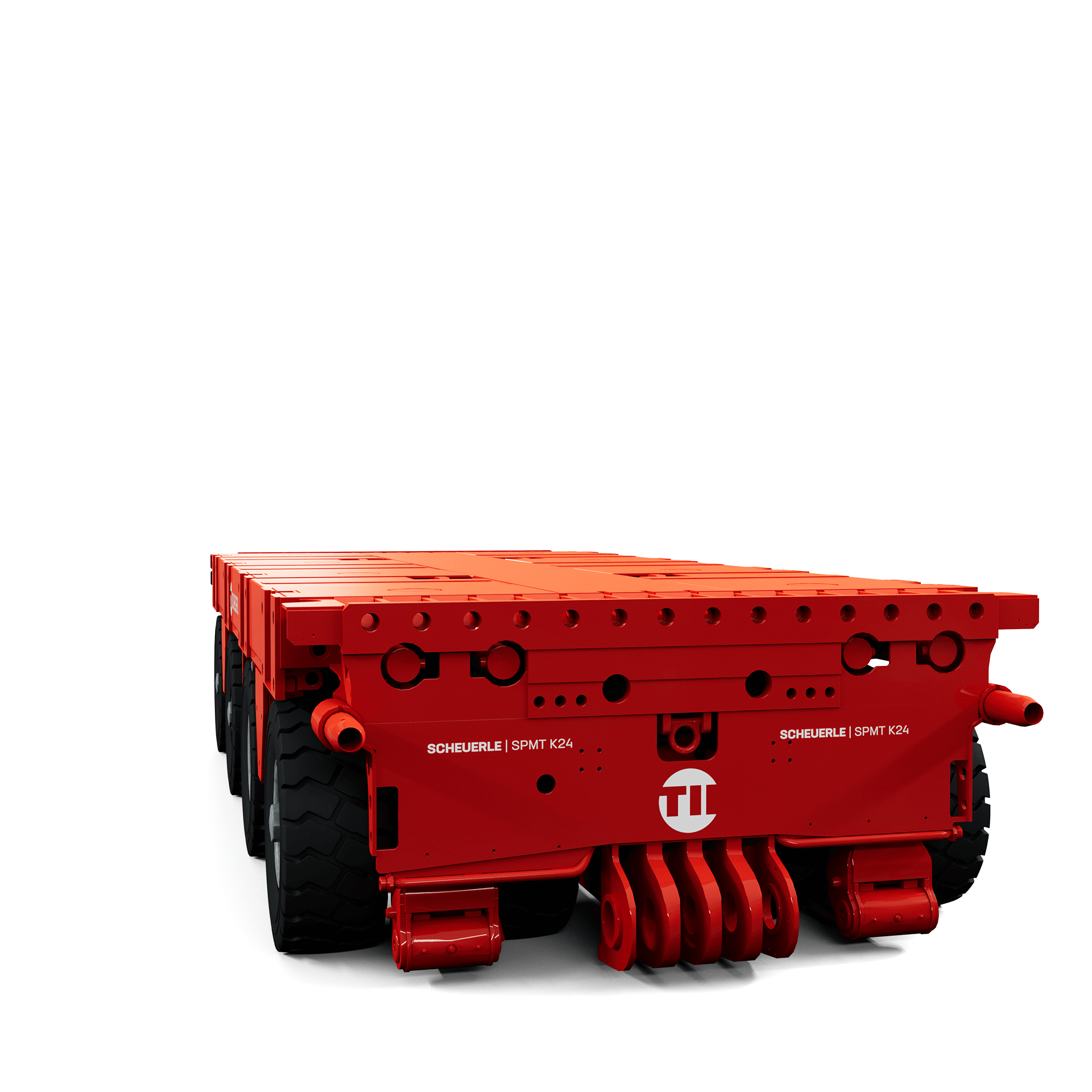

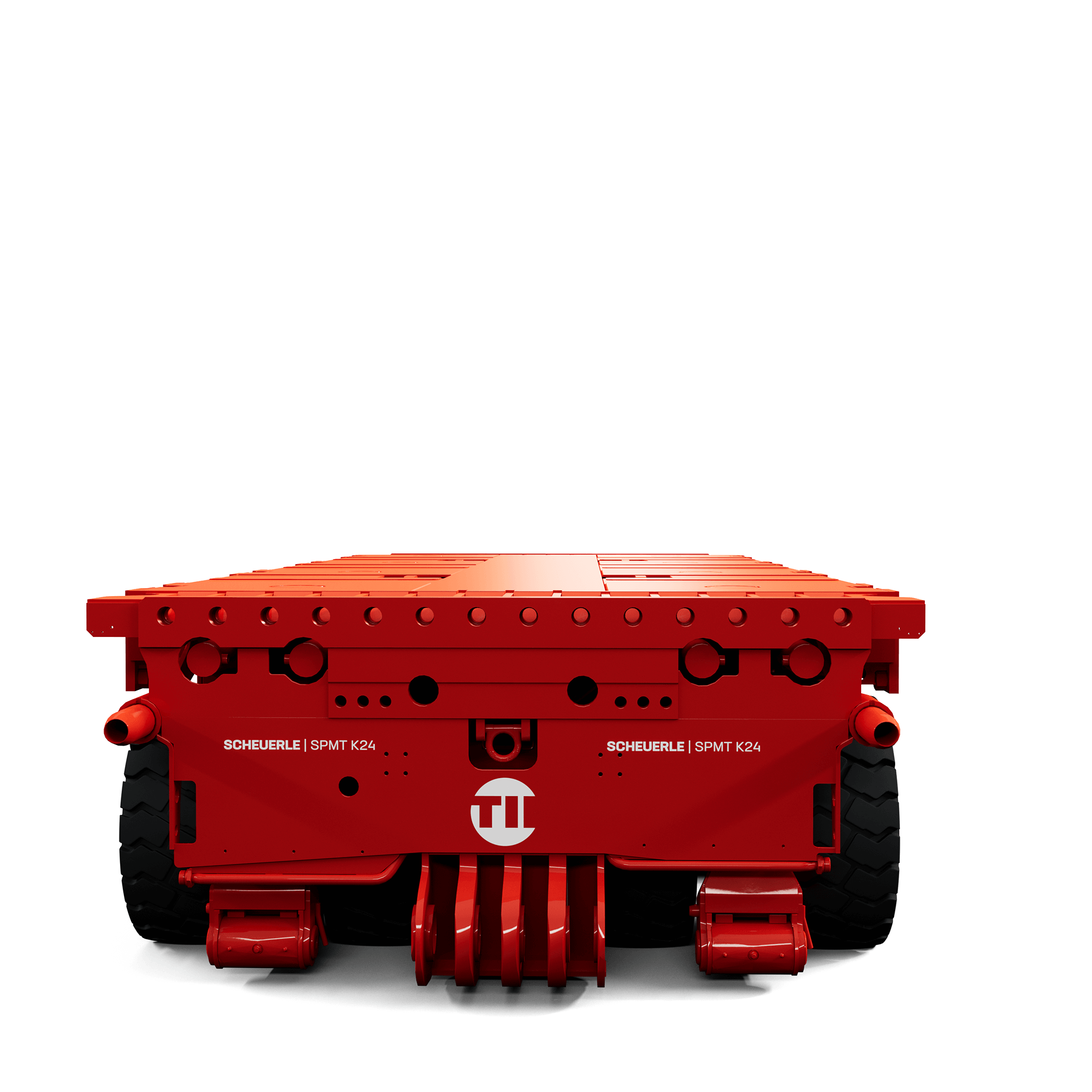

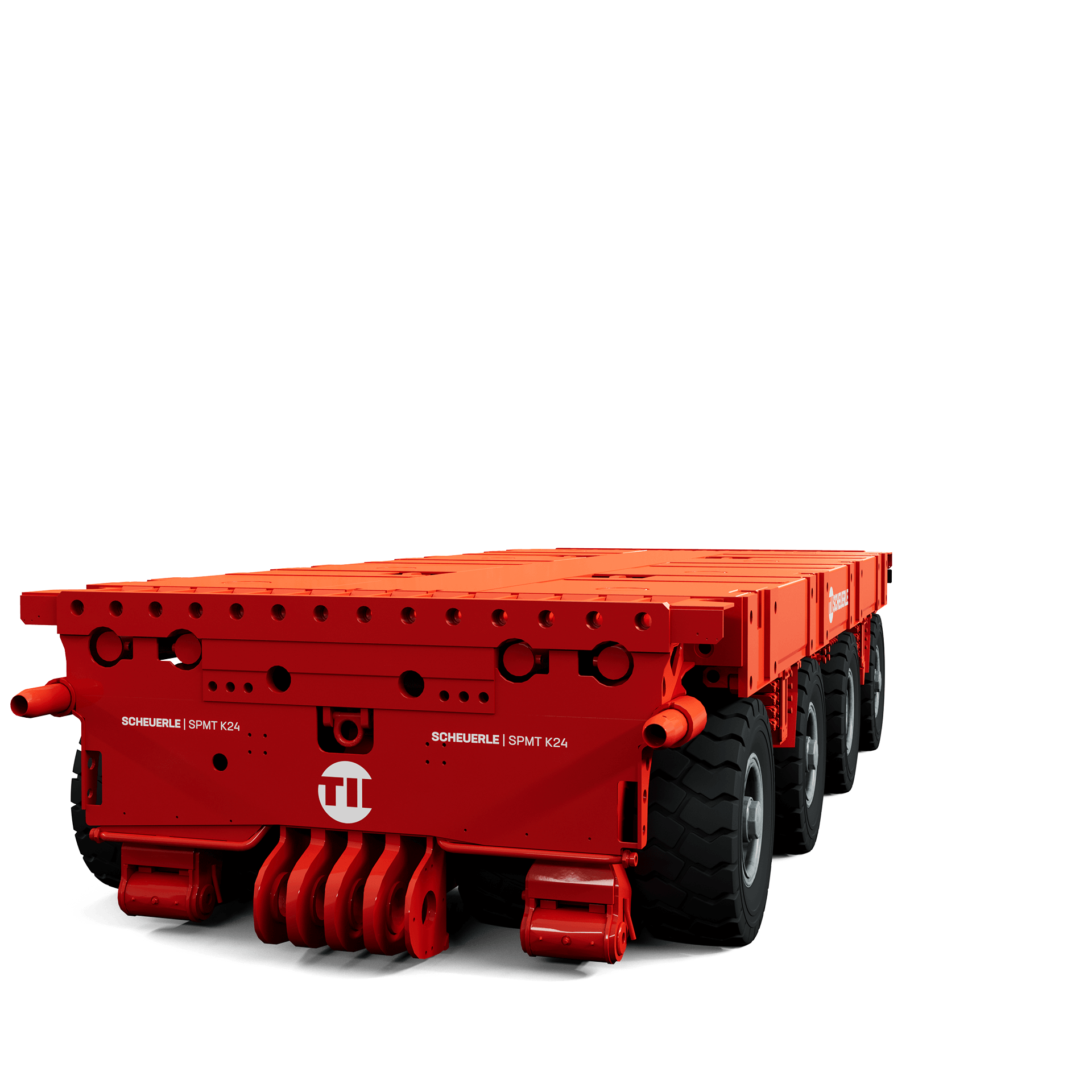

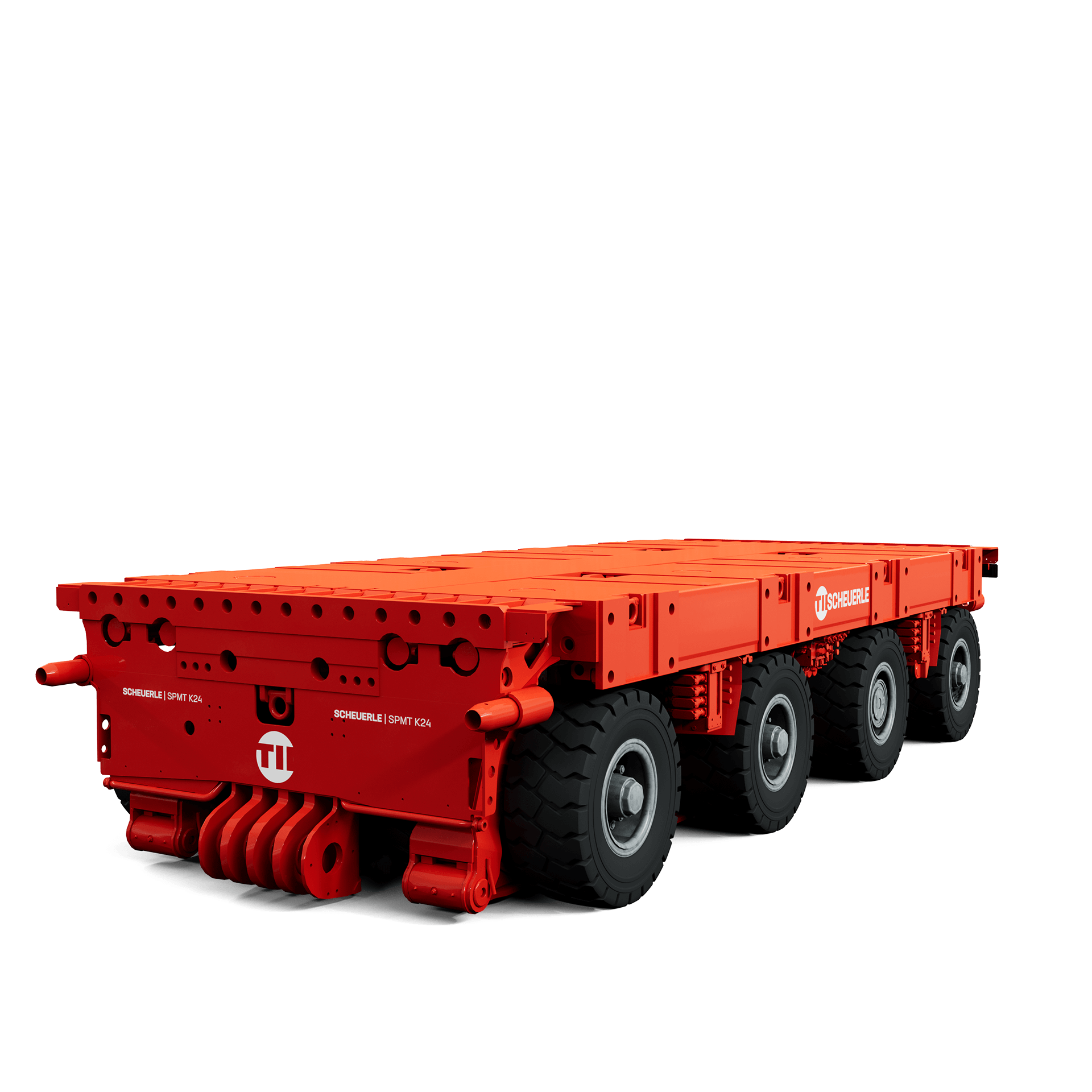

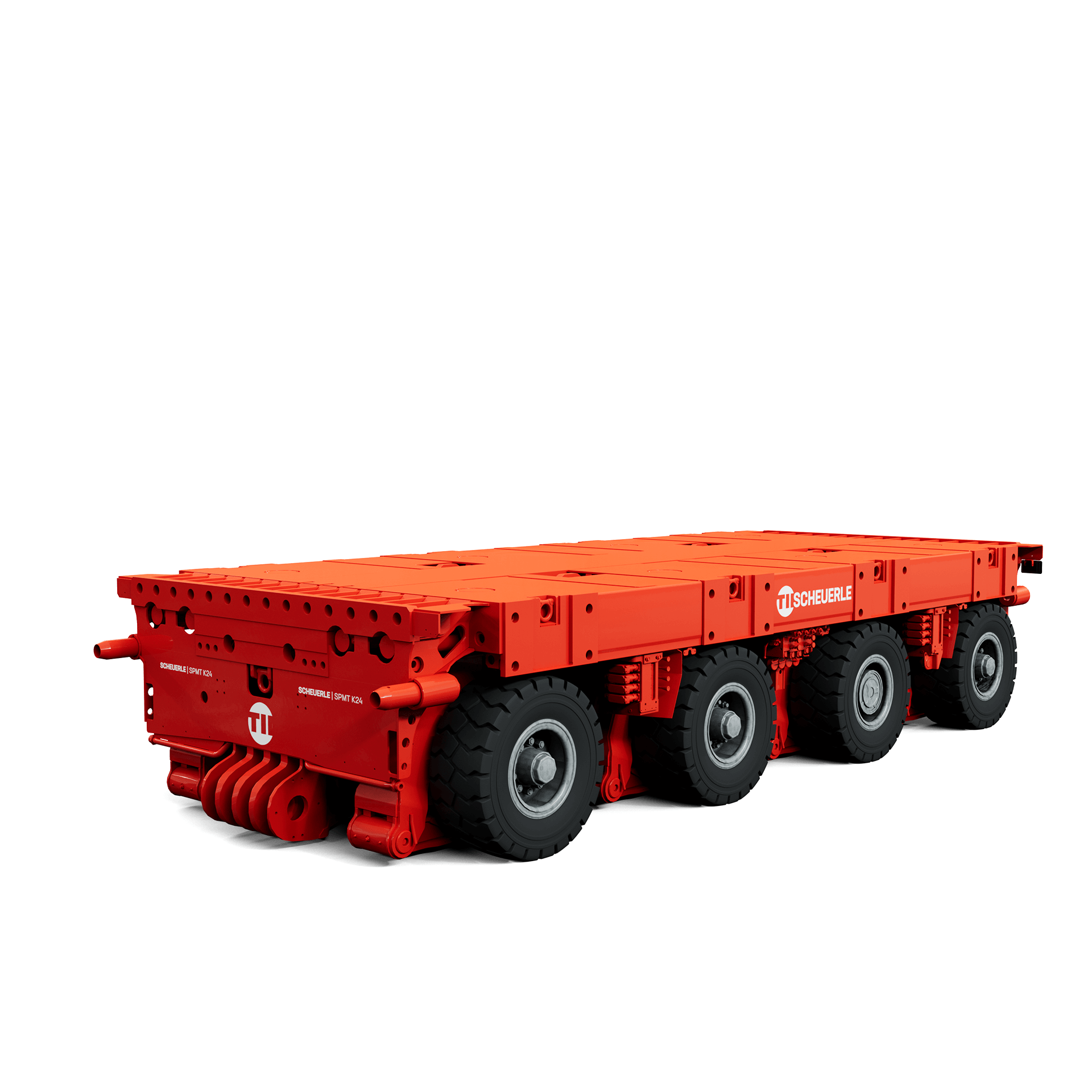

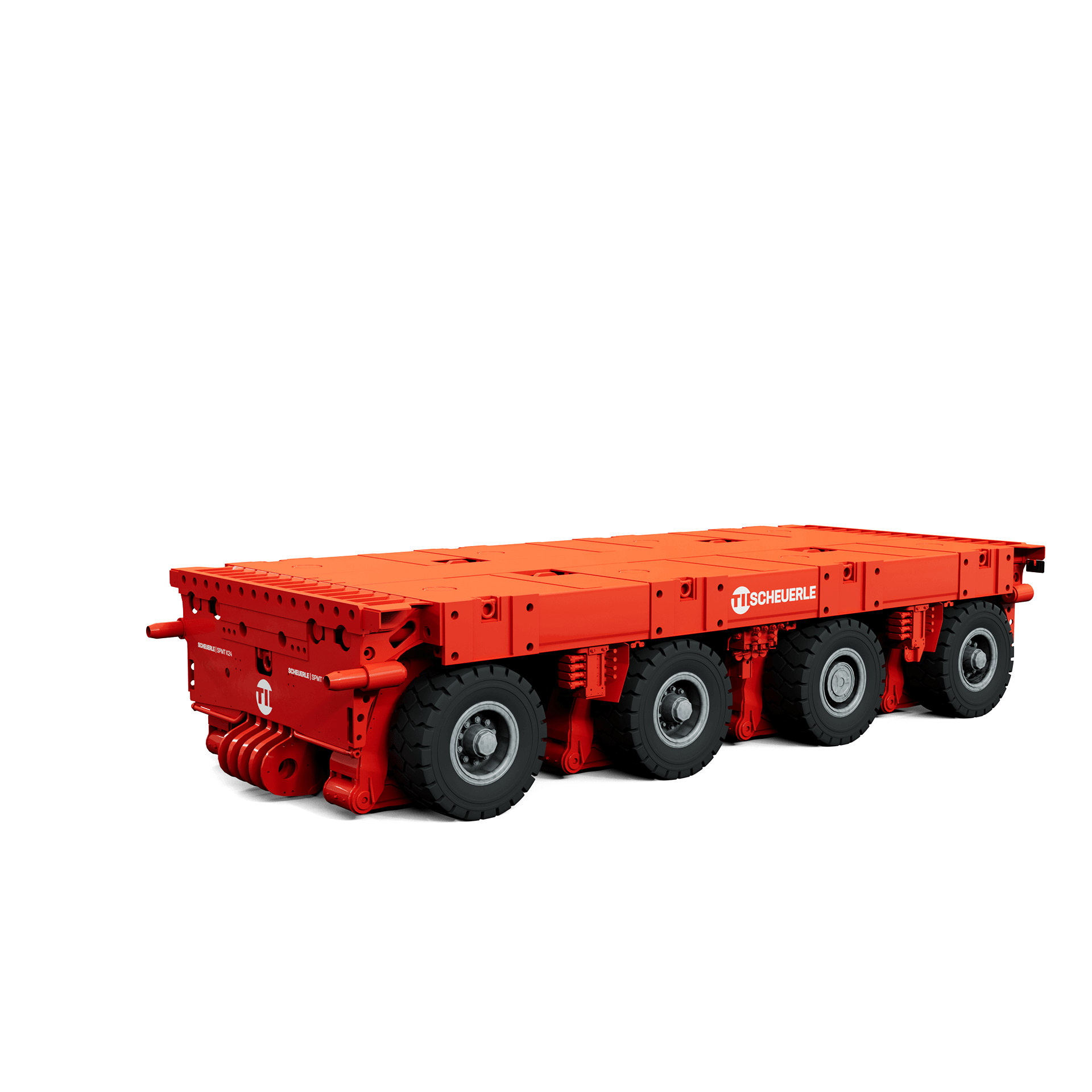

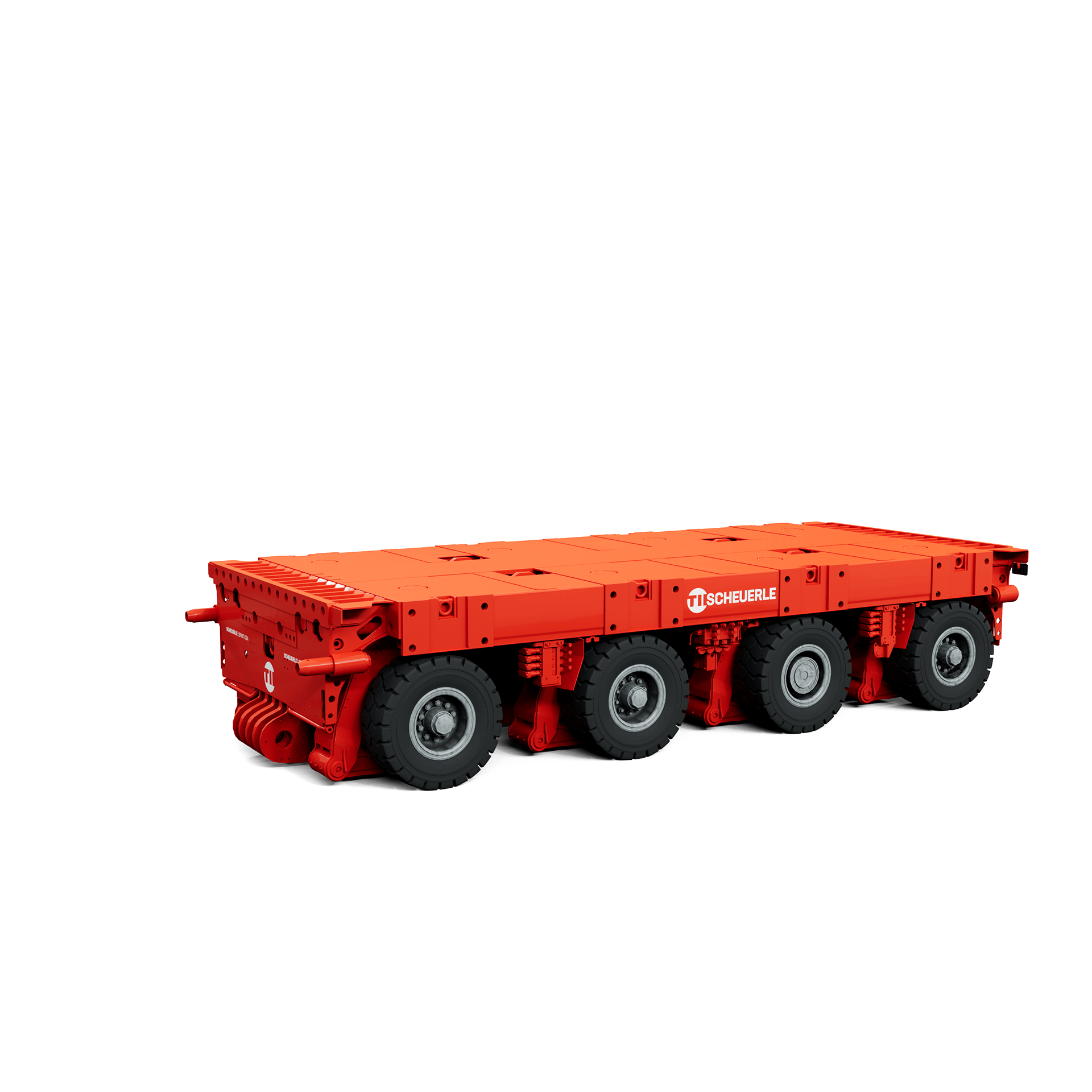

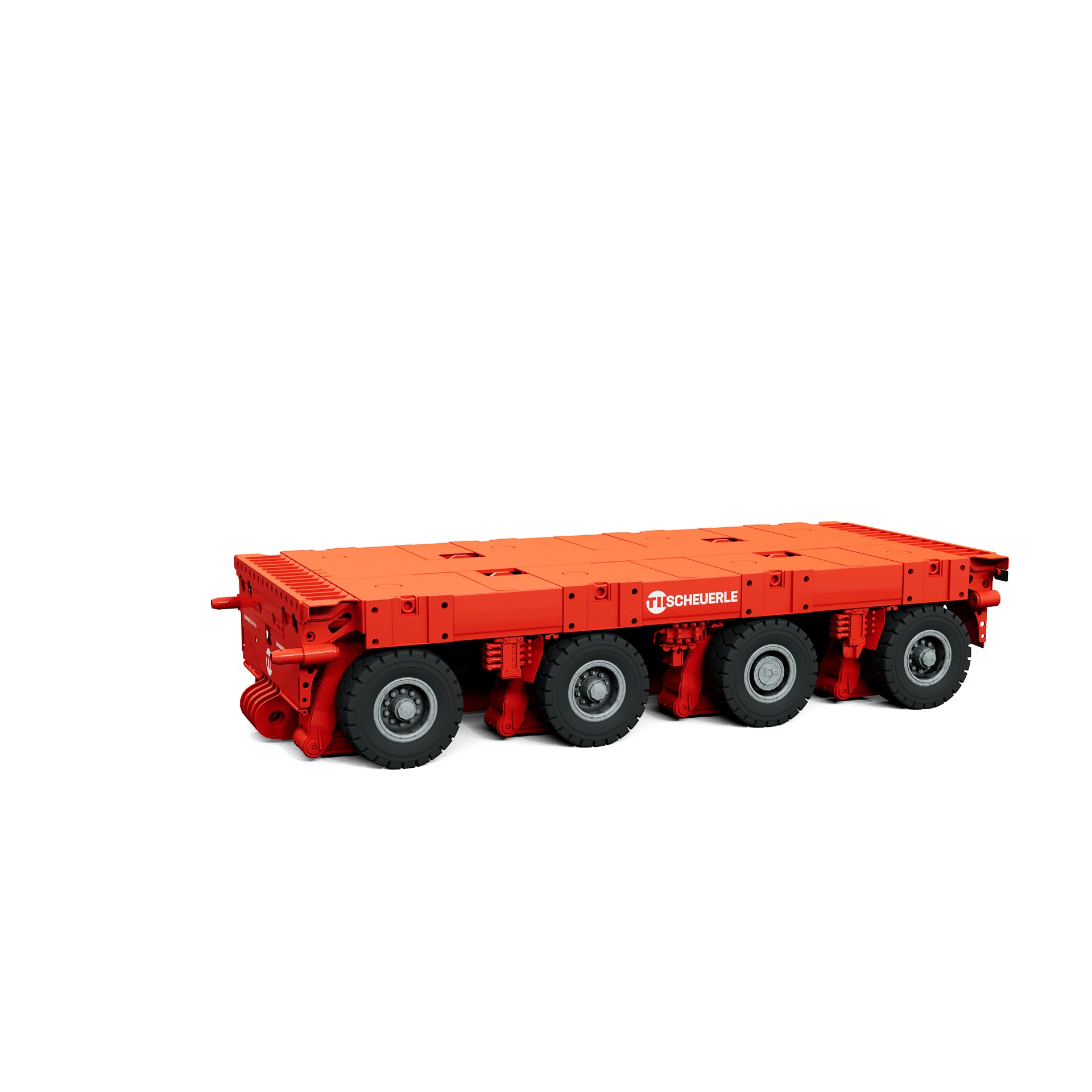

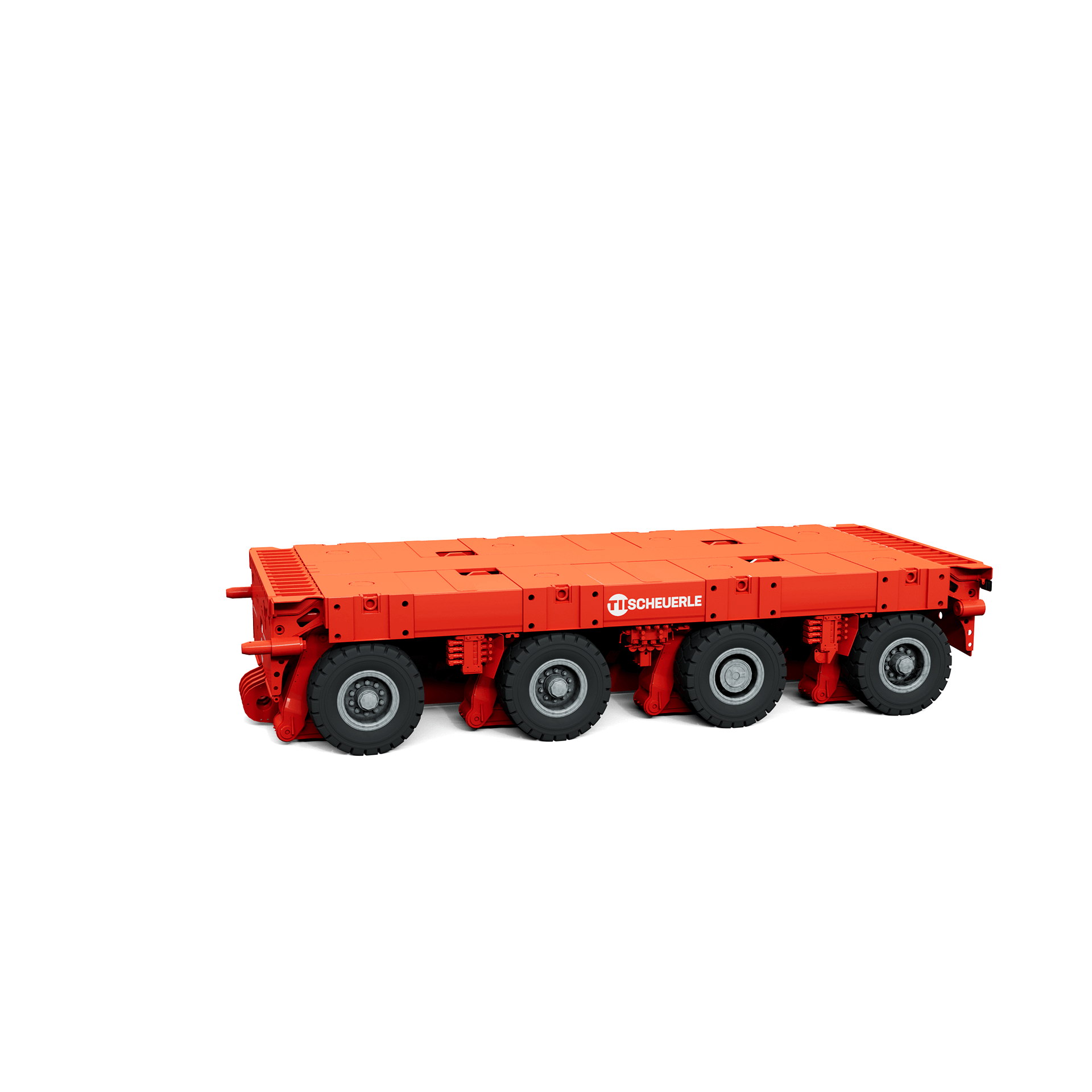

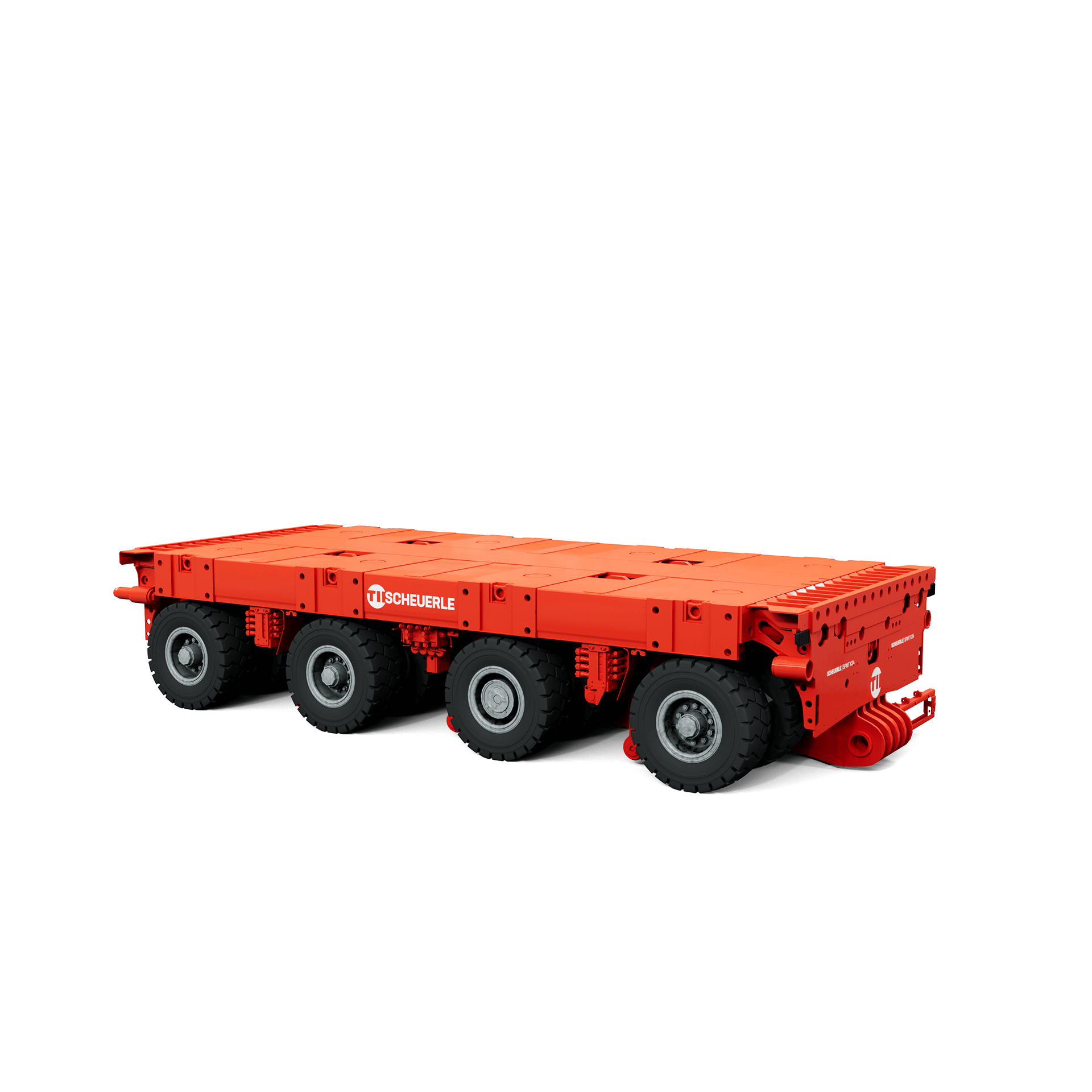

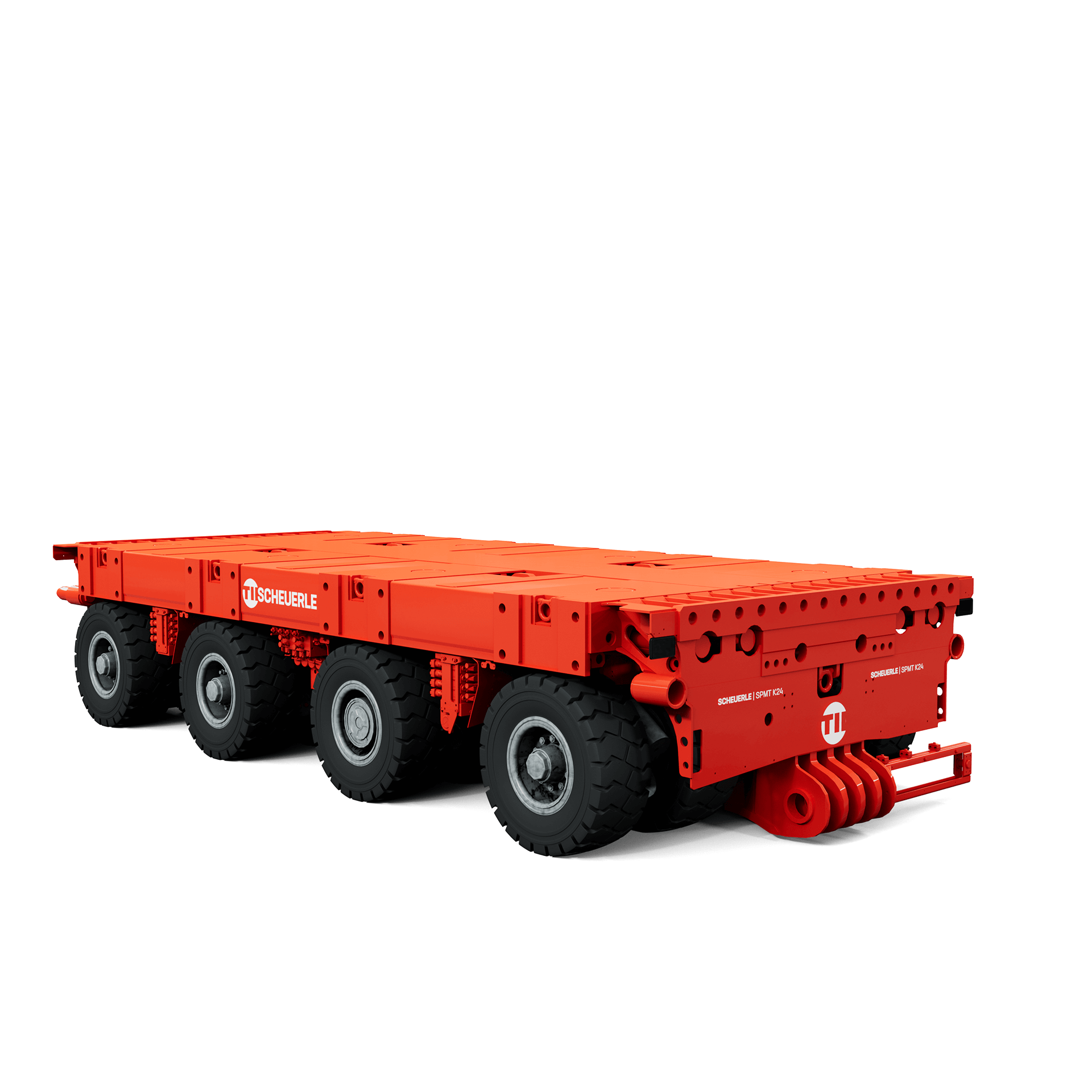

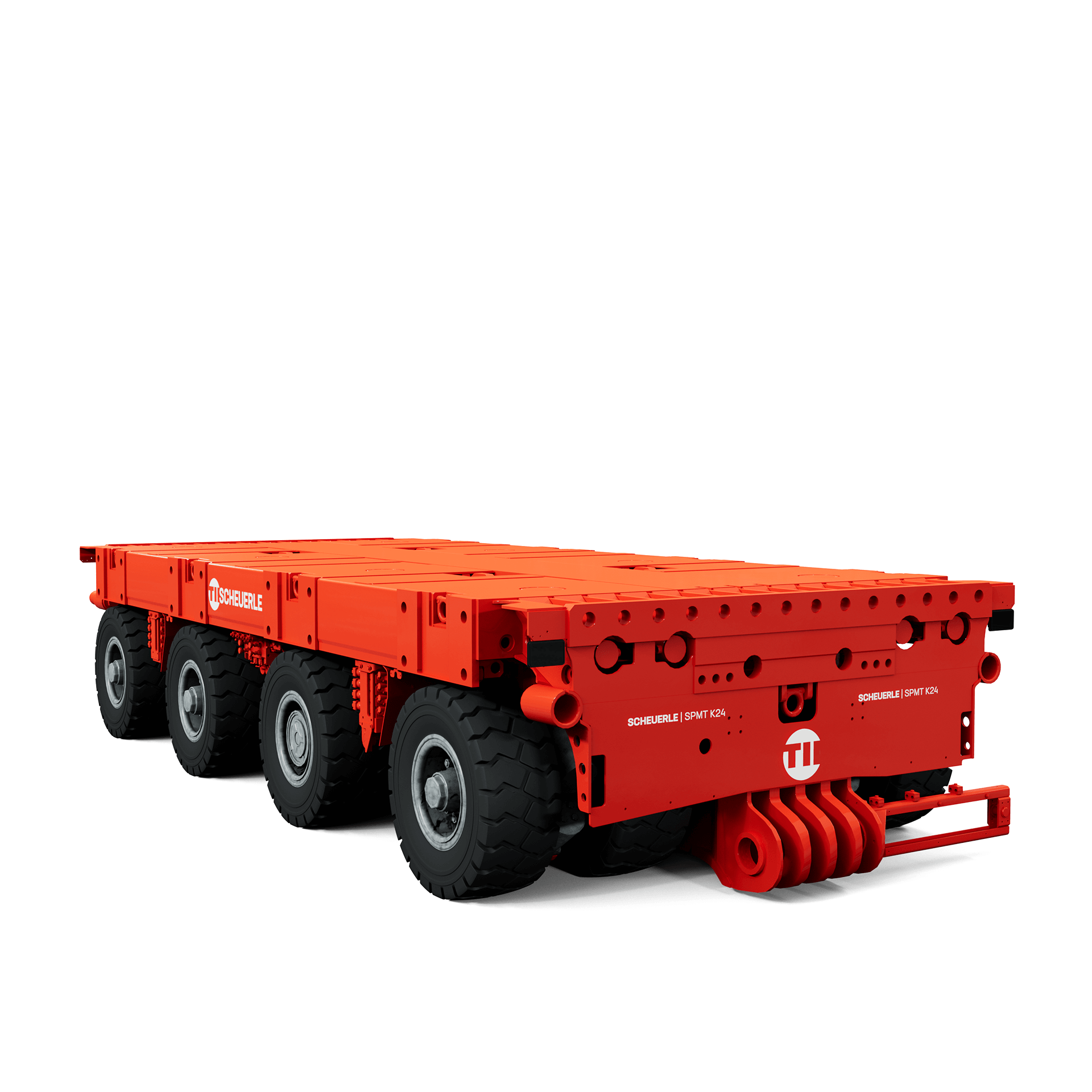

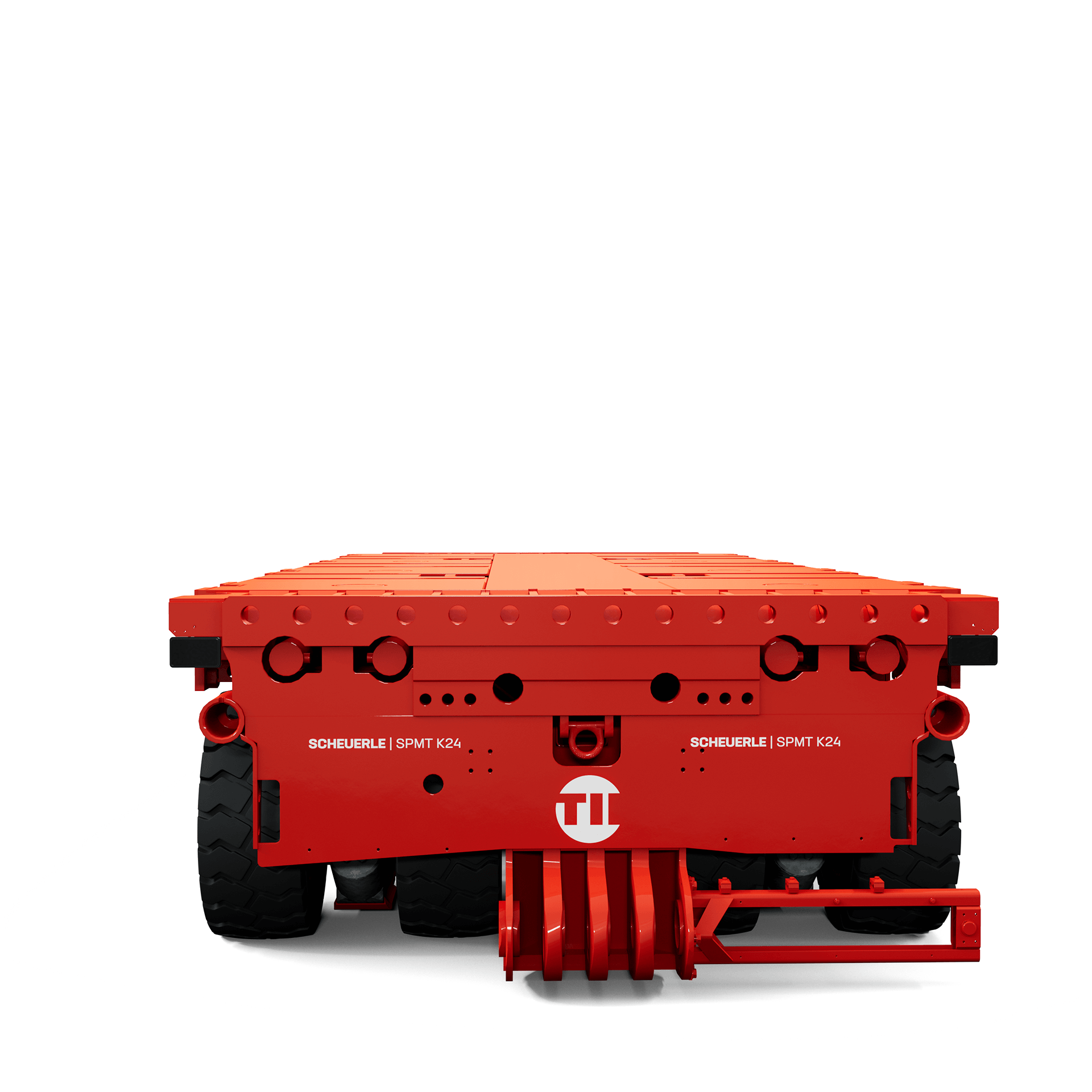

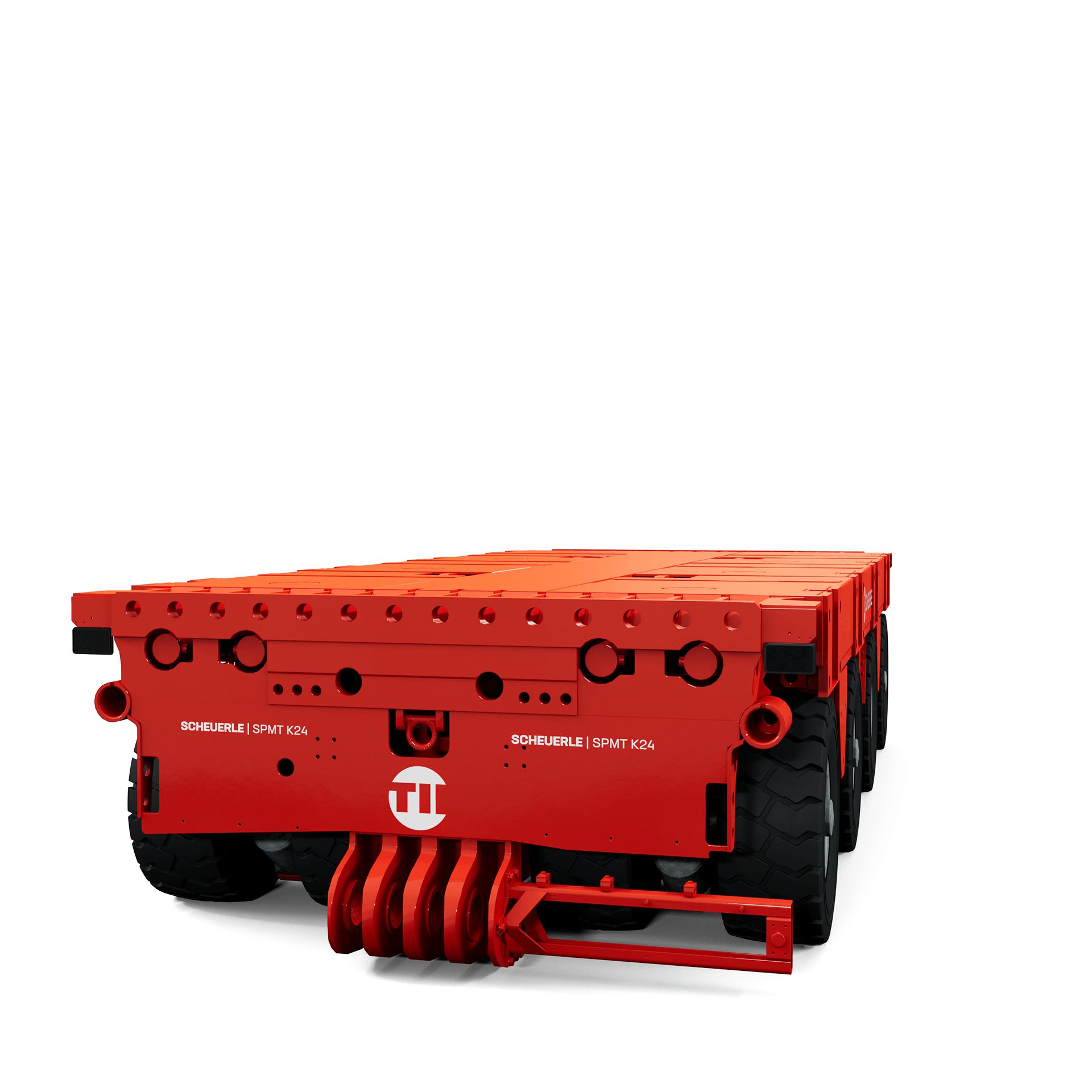

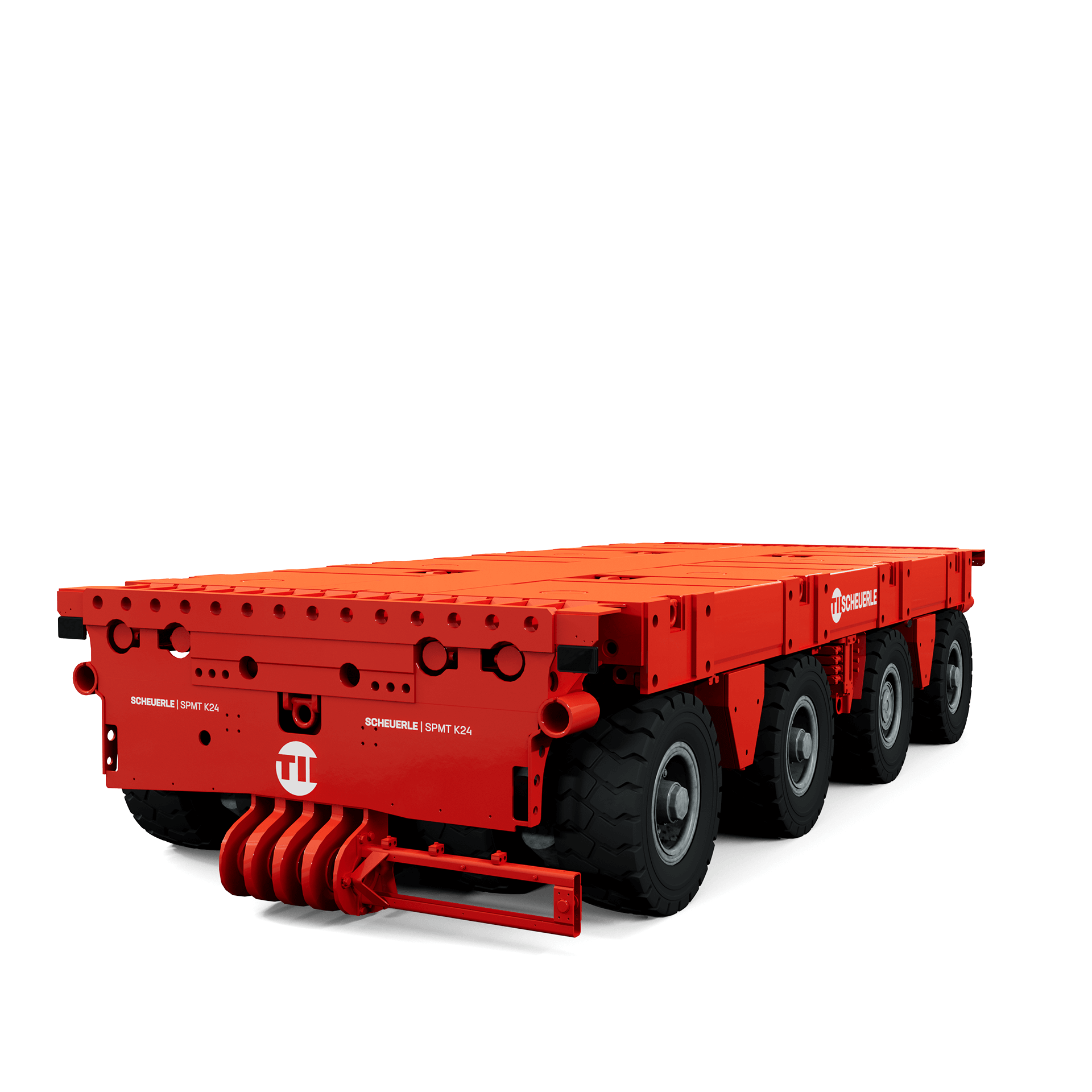

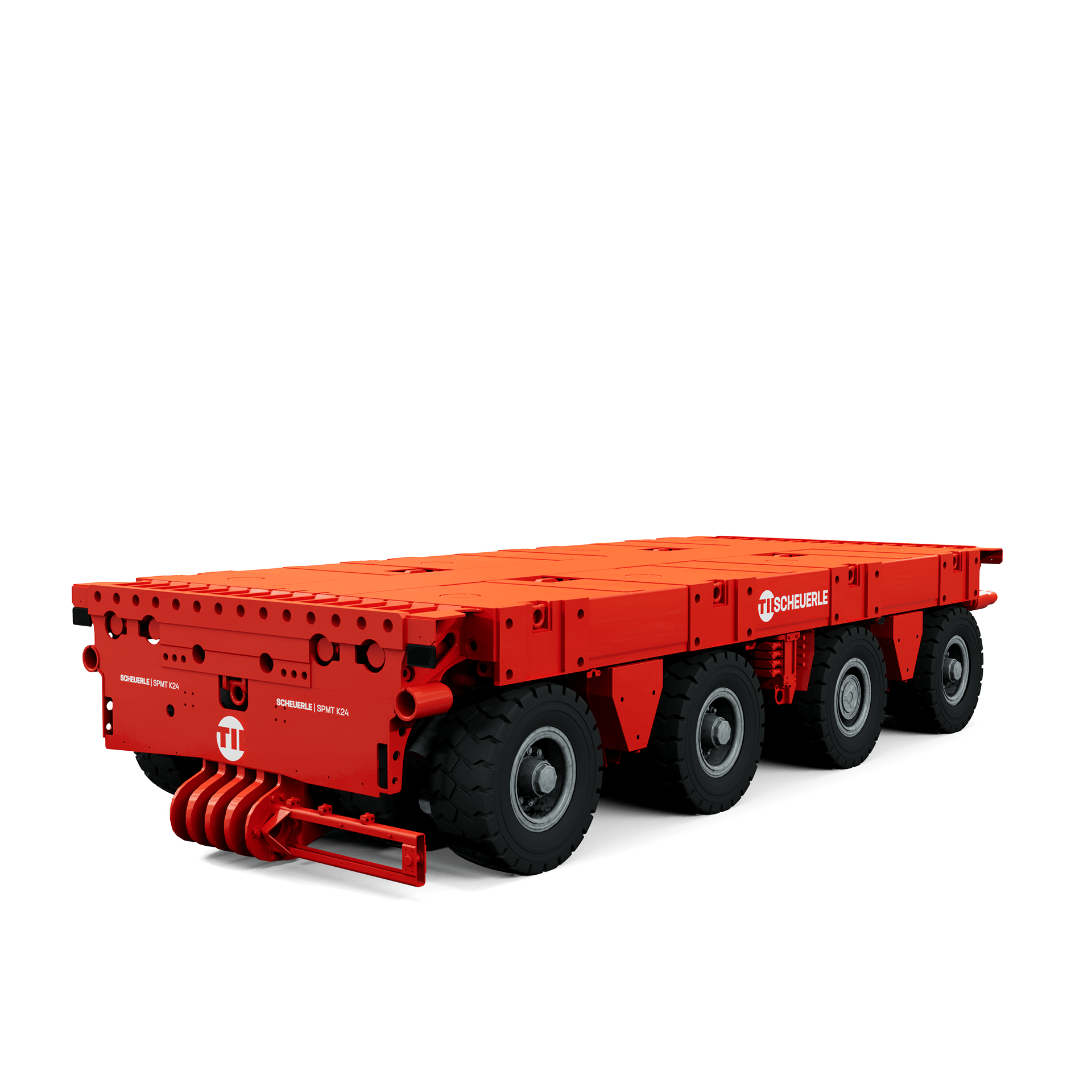

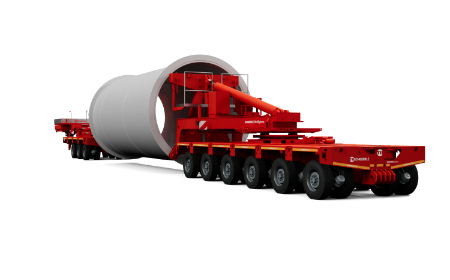

SCHEUERLE | SPMT K24

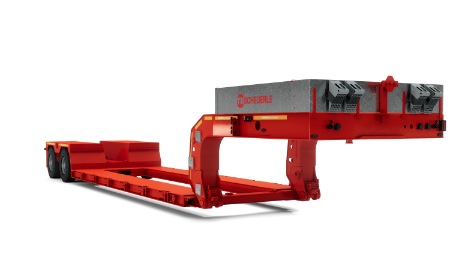

With the SCHEUERLE SPMT K24, TII has produced a proven, modular, self-propelled transporter that is used around the world. A comprehensive range of accessories turns the main components into a multifunctional transport system for accommodating heavy loads of almost any shape and size. Thanks to its economical design, the SCHEUERLE SPMT K24 can be loaded onto container flat racks and can therefore be flexibly used around the world.

Your advantages when you count on the SCHEUERLE SPMT K24:

- In container dimensions

- Unbeatable in a team – can be coupled with other SPMT units

- Customisable thanks to available performance packages

- Numerous steering programs